- What the ⁉️

- Current production process?

- New method:

- Upscaling: what can we get from 1 tonne of wood (424kg cellulose & 210kg lignine) ?

- How can this help us combat climate change?

- Current phenol/propylene production emissions (🧙♂️hock process) :

- Newly proposed phenol/propylene production GHG emissions (💡Sels-team):

- New production process: 😒lazy mode

- New production process: 🌬️renewables mode

- New production process: 🌳happy forest mode

- New production process: 🌬️renewables &🌳happy forest mode

- 😎Getting real 😎What about building a plant that:

New 🎉article [https://t.co/6HhczPncEj] out from the Sels Group research team @LeuvenU, conceptualising a sustainable wood biorefinery for low–carbon footprint chemicals production

🌳birch wood➡️🧪propylene, phenolic oligomers and phenol

@BartMuys @JoostVanAelst @KarelVA https://t.co/tLB71cy5re

What the ⁉️

Phenol/propylene: precursors for Bisphenol A (plastics), nylon rope [https://t.co/Qz0h5ITQ9g], foams/tires [https://t.co/SsViHz8ggv], detergents [https://t.co/zOZQOEoo31], etc, etc, …

⚠️Projected phenol demand = 13.5 million t in 2026

https://t.co/s8Q2BJwcbU https://t.co/yGbRtPllGr

Current production process?

…is called the 🧙♂️Hock process.

Downsize(s!)❓

- ⚫️fossil/non-renewable feedstock⚫️ methane!

- dangerous catalysts: hydroperoxide (🧨explosive) / sulph. acid (corrosive)

- yield of (only!) 5 %

- overproduction of acetone

New method:

😕Challenge

converting lignine (wood lignucellulose-constituent) -> phenol. Existing tech: only 3 % weight% yield

💡Found solution

phenol production from lignine with 20 and 50 weight% yield for respectively soft- and hardwood feedstocks

https://t.co/mTF2S1ohWd https://t.co/MXPnGfMmCe

Upscaling: what can we get from 1 tonne of wood (424kg cellulose & 210kg lignine) ?

1⃣New biorefinery process:

-> 311 kg crude oil -> 106 kg monomers

2⃣From monomers (using hydrogen, H2) :

–> 41kg phenol + 19,5 kg propylene + 0.8 kg ethylene https://t.co/zeiU1UvfP3

How can this help us combat climate change?

Current phenol/propylene production emissions (🧙♂️hock process) :

Global Warming Potential when producing from fossil feedstock:

- Phenol = ⚫️1.73 gCO2eq

- Propylene = ⚫️1.47 gCO2eq

[https://t.co/VX5wigjrjQ] https://t.co/lbkbNaqgD6

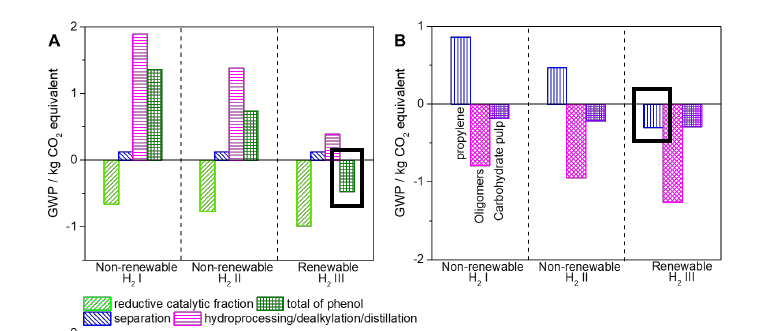

Newly proposed phenol/propylene production GHG emissions (💡Sels-team):

Assumptions:

🅰️production wt standard non-renewable H2 (8.2 kgCO2/kgH2)

🅱️standard Ecoinvent v3.3 forest management

- Phenol = 💡0.74 gCO2eq

- Propylene = 💡0.47 gCO2eq

[https://t.co/UWsigfoWvl] https://t.co/M3QgmJ659h

New production process: 😒lazy mode

Assumptions:

🅰️higher GWP H2 (11.9 kgCO2/kgH2)

🅱️standard Ecoinvent v3.3 forest (-0.45 kgCO2/kgwood)

- Phenol = 😒1.35 gCO2eq

- Propylene = 😒0.86 gCO2eq

[https://t.co/rlpA7X5axG] https://t.co/YkKcmXHogR

New production process: 🌬️renewables mode

Assumptions:

🅰️renewable H2 (0.97 kgCO2/kgH2)

🅱️standard Ecoinvent v3.3 forest management

- Phenol = 🌬️-0.47 gCO2eq

- Propylene = 🌬️-0.30 gCO2eq

(➖ sign = CO2 storage in oligomers and carbohydrate pulp)

[https://t.co/rlpA7X5axG] https://t.co/V2ia7GQBDA

New production process: 🌳happy forest mode

Assumptions:

🅰️standard non-renewable H2 (8.2 kgCO2/kgH2)

🅱️sustainable forest management (-1.78 kgCO2/kgwood)

- Phenol = 🌳-3.13 gCO2eq

- Propylene = 🌳-2.00 gCO2eq

[https://t.co/rlpA7X5axG] https://t.co/hAOjqtof6k

New production process: 🌬️renewables &🌳happy forest mode

Assumptions:

🅰️renewable H2 (0.97 kgCO2/kgH2)

🅱️sustainable forest management (-1.78 kgCO2/kgwood)

- Phenol = 🌬️🌳-3.13 gCO2eq

- Propylene = 🌬️🌳-2.00 gCO2eq

[https://t.co/rlpA7X5axG] https://t.co/cXVk0KJydu

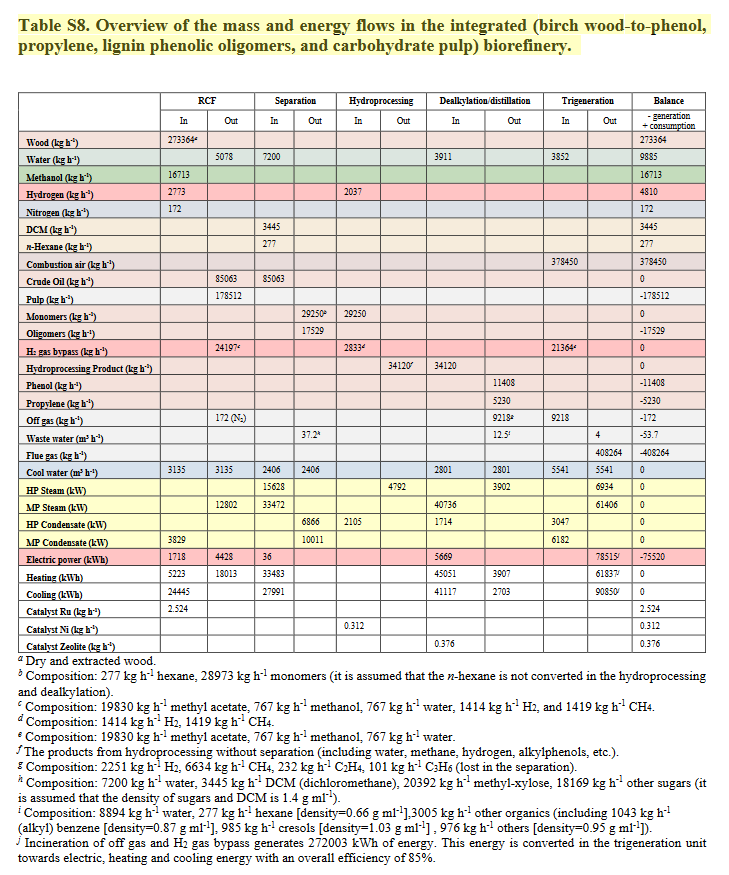

😎Getting real 😎What about building a plant that:

takes in 273 ton (t) of wood

& produces:

11.5t phenol (99% purity) 5.2t propylene (99.9% purity) 17t lignin olimers 178t pulp 75 MWh

…per year?

Mass & Energy Balance: https://t.co/3SujRWAn6C https://t.co/v9V3np1sTr

First concern/question: Is there enough wood for this type of plant?

According to Prof. Sels - because of the shrinking paper industry in Europe, “there is currently a surplus of wood production in Europe” https://t.co/NZcFpm4RnB

Second question: how much would this cost?

Total CAPEX: 477 MM€ https://t.co/f7lZfws2Jy

With:

- current/fixed prices/infrastructure cost

- 20 year project lifetime

- 8766 h operation per year

- depreciation in 10 years

- 50% income tax

Full list: https://t.co/caAgJbx9ab https://t.co/7GwayPS4fV

Note: the cost and profitability are mostly dependent on the product and feedstock prices [https://t.co/h8K6rXWdBl]

Assumed product/manufacture prices: see attached figure & https://t.co/bKotCiq0Gf + https://t.co/gNAznRRyik https://t.co/QLyyFTSgnY

A good example of the high potential of biomass utilization in the refining industry recognized by the EU High Level expert Group on energy-intensive industries [https://t.co/DzVDubmRao] in its latest masterplan report [https://t.co/XQ4KxWxHhK] https://t.co/k1p0sdg7Rh